2025 Guide: How to Safely Disconnect Your Motor in 5 Easy Steps

In today's fast-paced industrial landscape, safely managing equipment operation is critical. As we prepare for an era of enhanced automation and efficiency, understanding the nuances of motor disconnect becomes paramount. Expert Tom Harris, a renowned figure in the electrical engineering field, emphasizes that “a proper motor disconnect process not only ensures safety but also prolongs the lifespan of your equipment.” This insight highlights the significance of effectively disconnecting motors in various applications.

The process of safely disconnecting a motor may seem straightforward, but it requires attention to detail and adherence to best practices. As businesses look towards 2025, implementing a systematic approach to motor disconnect will play a crucial role in minimizing risk while maximizing productivity. In this guide, we'll provide you with five easy steps to ensure you can carry out this operation with confidence and care. Whether you are a seasoned professional or a newcomer to the field, mastering the art of motor disconnect is essential for the safety and efficiency of any operation.

Understanding Your Motor: Types and Functionality

Understanding your motor is crucial for both safety and efficiency in various applications. There are several types of motors commonly used, each serving distinct functionalities. Electric motors, for instance, convert electrical energy into mechanical energy and are widely utilized in industrial machinery, appliances, and electric vehicles. According to the International Electrotechnical Commission (IEC), electric motors account for about 45% of global electricity consumption, emphasizing their significance in energy efficiency discussions.

On the other hand, combustion engines, which burn fuel to create mechanical power, are prevalent in transportation sectors. The U.S. Department of Energy indicates that internal combustion engines typically have an energy efficiency of around 20-30%, suggesting significant room for improvement compared to electric counterparts. Understanding these differences is vital for users aiming to make informed decisions about energy consumption and motor selection. Thus, recognizing the specific type of motor and its functional capability helps in maintaining optimal operational performance while also contributing to sustainability efforts in various industries.

Preparing for Disconnection: Safety Precautions to Take

When preparing to disconnect your motor, taking the right safety precautions is crucial to ensuring a safe process. According to the National Fire Protection Association (NFPA), electrical accidents are responsible for nearly 10% of all workplace fatalities in the United States. Therefore, before starting the disconnection, it is essential to assess the environment for potential hazards such as wet surfaces, clutter, or the proximity of flammable materials. Ensure that the area is well-ventilated, especially if the motor generated heat during operation, to prevent any risk of thermal shock or electrical fires.

Additionally, the Occupational Safety and Health Administration (OSHA) highlights the importance of using personal protective equipment (PPE) when handling electrical components. This includes insulated gloves, safety goggles, and non-conductive footwear, which significantly reduce the risk of electrical shock. Further, it’s advisable to verify that all power sources are appropriately locked and tagged according to safety protocols. Implementing a strict lockout/tagout (LOTO) procedure ensures that no unexpected power connections occur while disconnection is being carried out, enhancing safety for everyone involved in the operation.

2025 Guide: How to Safely Disconnect Your Motor in 5 Easy Steps - Preparing for Disconnection: Safety Precautions to Take

| Step | Action | Safety Precautions | Tools Required |

|---|---|---|---|

| 1 | Turn Off Power Supply | Ensure main switch is off; verify with a multimeter. | Multimeter, Safety Gloves |

| 2 | Disconnect Battery | Remove negative terminal first to avoid sparks. | Wrench, Insulated Tools |

| 3 | Loosen Connection Clamps | Follow proper procedure to avoid injury. | Screwdriver, Pliers |

| 4 | Mark Wires for Reconnection | Use colored tape to identify wires. | Colored Tape, Labels |

| 5 | Remove Motor | Use equipment to safely lower motor if needed. | Hoist, Strap |

Step-by-Step Guide to Disconnecting Your Motor Safely

When it comes to safely disconnecting your motor, following a systematic approach is paramount. According to a report by the Occupational Safety and Health Administration (OSHA), improper motor disconnection can lead to serious workplace accidents, contributing to over 25,000 electrical injuries annually in the United States alone. To minimize risks, it's crucial to implement a step-by-step process that ensures safety for both the operator and the equipment.

The first step in safely disconnecting a motor involves properly shutting down the power source. This means turning off all relevant breakers and ensuring that the motor is completely shut down before proceeding. Next, utilizing lockout/tagout (LOTO) protocols can help prevent the accidental re-energization of the equipment. A recent industry study indicated that implementing LOTO procedures can reduce workplace accidents by up to 30%.

After securing energy sources, checking for residual voltage with a multimeter is essential to confirm that there is no active electricity flowing before you proceed with any physical disconnection. Following these precautions not only protects personnel but also extends the lifespan of the motor by preventing damage caused by improper shutdowns.

Common Mistakes to Avoid When Disconnecting Your Motor

When disconnecting your motor, it’s crucial to be aware of common mistakes that can lead to costly damage or safety hazards. One frequent error is neglecting to power down all electrical sources before starting the disconnection process. Always ensure that the power supply is completely turned off and properly locked out to prevent accidental reactivation. Failing to do this can result not only in equipment damage but also pose serious safety risks for anyone involved in the process.

Another common mistake is not taking notes or labelling wires and connections as you disconnect them. Without a clear understanding of how everything is interconnected, reassembling the motor can become a tedious and error-prone task. Use color-coded labels or a detailed diagram to document each connection; this will save time and reduce frustration when it’s time to reconnect. Additionally, be cautious of loose wires left dangling, as they can lead to shorts or other electrical issues if not handled correctly. Taking these precautions can help ensure a smooth and safe disconnection process.

Post-Disconnection: Maintenance and Inspection Tips

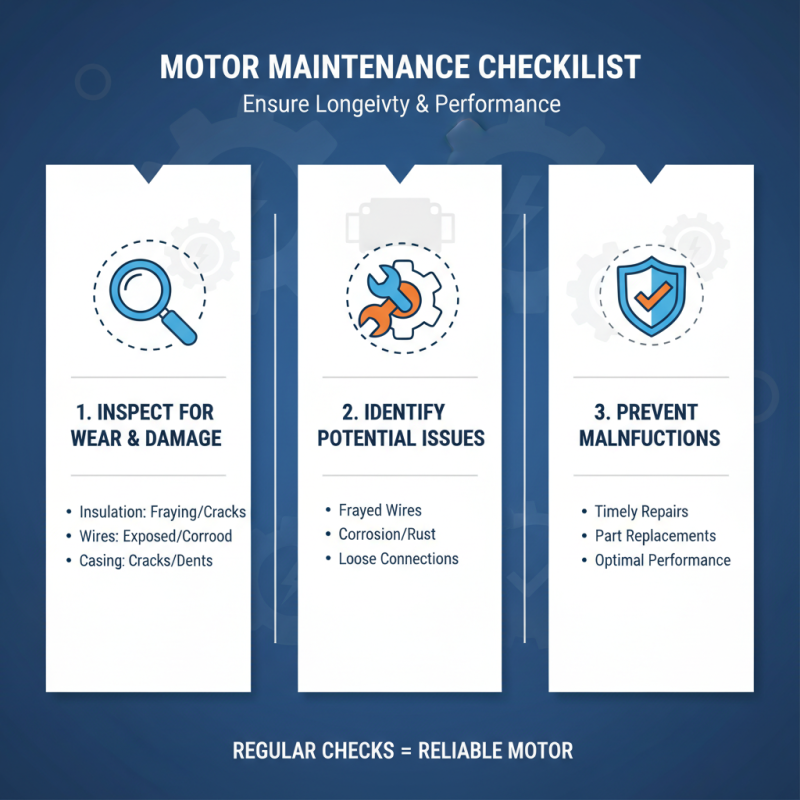

After safely disconnecting your motor, the next crucial step is to carry out thorough maintenance and inspection to ensure its longevity and optimal performance. Begin by checking for any signs of wear or damage to the motor components, such as insulation, wires, and casing. Look for frayed wires, cracks, or corrosion, as these can lead to future malfunctions. Regular inspections help identify potential issues before they become significant problems, allowing for timely repairs or replacements.

Tips for maintaining your motor include cleaning the internal parts to remove dust and debris, which can hinder performance and cause overheating. Use a vacuum or compressed air to clean out vents and cooling fans. Furthermore, lubricate moving parts with appropriate oils to reduce friction, making sure not to over-lubricate, as this can attract dirt and lead to more issues. Be sure to check the connections and hardware frequently, tightening any loose screws or bolts to prevent vibrations from causing additional damage over time.

Lastly, it's vital to document all maintenance activities. Keeping a log of inspections, maintenance, and repairs will provide a useful reference for future upkeep and help track the motor's condition over time. This practice not only enhances safety but also contributes to the overall efficiency and lifespan of your motor.

Related Posts

-

Best 10 Circuit Control Techniques You Need to Know for Your Projects

-

Top 10 Tips for Choosing the Best Power Controller for Your Needs

-

Top 5 Circuit Power Solutions Driving Efficiency in Modern Electronics

-

Essential Tips for Improving Motor Control in Daily Activities

-

How to Choose the Right Soft Starters for Your Industrial Applications

-

2025 Guide to Motor Control Centers: Features, Benefits, and Selection Tips

Skip to content

Skip to content