Why is Motor Disconnect Important for Safe Electrical Operations

In the realm of electrical safety, the significance of a motor disconnect cannot be overstated. Motor disconnects serve as critical components in electrical systems, ensuring the safe operation and maintenance of motor-driven equipment. According to the National Electrical Manufacturers Association (NEMA), proper isolation of electrical motors can reduce the risk of accidents, protecting both personnel and equipment. Furthermore, the U.S. Occupational Safety and Health Administration (OSHA) highlights that nearly 10% of workplace electrical incidents are associated with improper isolation procedures during maintenance activities.

With the ongoing advancements in technology and an increasing reliance on automated systems, the probability of encountering hazardous situations during electrical work on motors escalates. Reports indicate that over 300 deaths and countless injuries occur each year due to electrical mishaps, many of which could be mitigated through the use of effective motor disconnects. This emphasizes the necessity for diligent adherence to safety protocols and the integration of motor disconnect devices in electrical design. As industries prioritize safety, understanding the functionality and importance of motor disconnect systems becomes imperative for sustaining a secure working environment.

Understanding Motor Disconnect Switches and Their Purpose

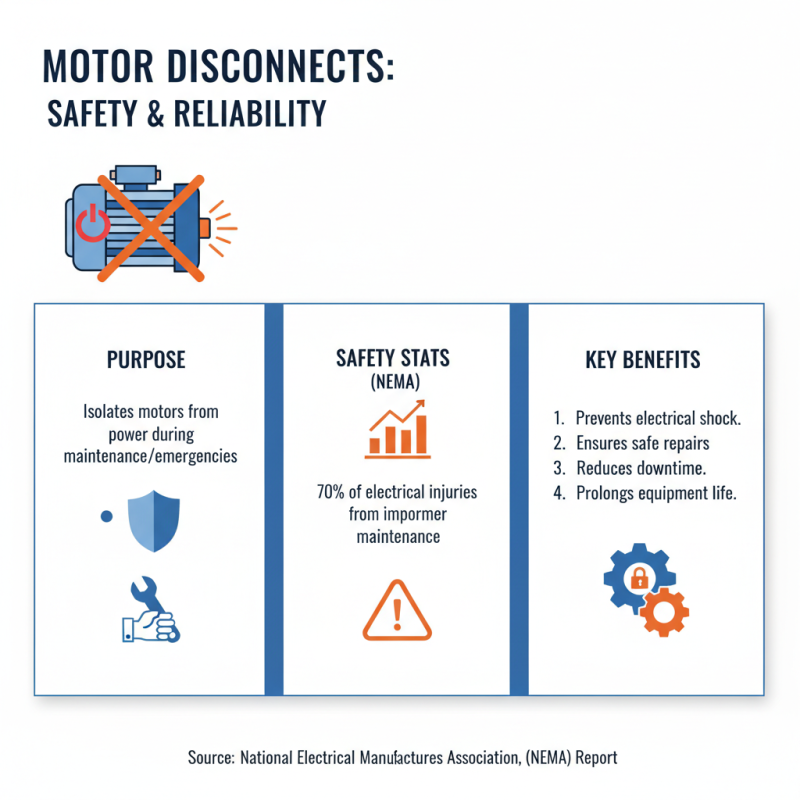

Motor disconnect switches play a crucial role in ensuring the safe operation of electrical systems that involve motors. These switches are designed to provide a reliable means of disconnecting the power supply to a motor, allowing for safe maintenance and troubleshooting. Their primary function is to ensure that when maintenance personnel need to work on motor-driven equipment, the power is effectively cut off, reducing the risk of accidental startup and potentially hazardous situations.

In addition to facilitating safe maintenance procedures, motor disconnect switches also contribute to overall system reliability and efficiency. They are often equipped with visual indicators to show whether the circuit is open or closed, enhancing operational awareness. Moreover, these switches help to protect the motor and associated equipment from electrical faults by providing a means to isolate individual components within a larger system. This isolation is critical in preventing damage to machinery and ensuring that any electrical issues can be identified and rectified without affecting other operational aspects.

Key Safety Benefits of Motor Disconnect in Electrical Systems

Motor disconnects are critical components in electrical systems, serving as a crucial safety mechanism for operators and maintenance personnel. One of the primary benefits of utilizing motor disconnects is the enhanced safety they provide during maintenance activities. When a motor disconnect is properly engaged, it ensures that the electrical supply to the motor is completely cut off, significantly reducing the risk of accidental electric shocks or short circuits. This allows technicians to perform their work without the fear of sudden re-energization while they are handling electrical components.

Additionally, motor disconnects contribute to equipment longevity and reliability. By allowing operators to isolate motors from the power source, they can effectively perform regular inspections and maintenance without disturbing the entire system. This isolation can prevent larger-scale failures by enabling timely detection of wear or malfunction. Furthermore, in emergency situations, motor disconnects facilitate quick response times, allowing personnel to swiftly shut off power to minimize damage and enhance safety. Overall, the integration of motor disconnects in electrical systems is a fundamental practice to uphold operational safety and efficiency.

Essential Components of Electrical Disconnects for Motors

When discussing the essential components of electrical disconnects for motors, safety and reliability emerge as paramount considerations. A motor disconnect serves as a critical safety device that provides a means to isolate electrical motors from the power supply during maintenance or in emergencies. According to a report by the National Electrical Manufacturers Association (NEMA), approximately 70% of workplace electrical injuries stem from improper maintenance practices, highlighting the need for effective isolation solutions.

Key components of electrical disconnects include operating mechanisms, enclosures, and appropriate voltage ratings. A robust operating mechanism allows for quick and efficient disconnection, which is vital during electrical fault conditions. Enclosures must be designed to withstand environmental factors such as moisture, dust, and corrosive agents. Furthermore, disconnects should be chosen based on their voltage rating to ensure they can handle the operational load, as mismatched ratings can lead to equipment failure and safety hazards.

**Tips:** Always conduct a thorough risk assessment before selecting motor disconnects. Ensure that you choose models certified for the specific environmental conditions they will be operating in. Regularly inspect and maintain disconnects to ensure they function correctly, reducing the likelihood of unforeseen incidents during operation.

Best Practices for Implementing Motor Disconnect Procedures

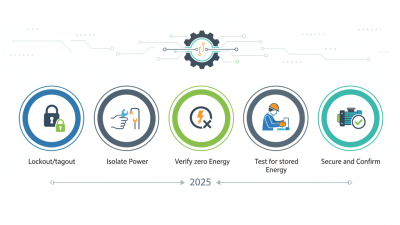

Implementing effective motor disconnect procedures is essential for maintaining safety in electrical operations. A motor disconnect switch serves as a critical control point, allowing operators to safely isolate motors from the power supply when maintenance or emergency response is required. Ensuring that all personnel are trained on how to properly use these disconnects can significantly reduce the risk of accidents or injuries associated with unexpected motor startups.

When establishing motor disconnect procedures, it’s vital to adhere to best practices. First, clearly label all disconnect switches to prevent confusion during operation. This small step enhances safety by ensuring that anyone working in the area can quickly identify the correct switch to use. Additionally, regular inspections and maintenance of disconnect switches are necessary to ensure they function properly when needed. Keeping these devices in optimal condition helps prevent failure during critical moments.

Tips: Always implement a lockout/tagout (LOTO) system to control hazardous energy during maintenance activities. This practice not only complies with safety regulations but also reinforces a culture of safety among employees. Furthermore, training sessions should include hands-on simulations so that workers can practice using motor disconnect switches in a controlled environment, ingraining the correct procedures into their routines.

Common Misconceptions About Motor Disconnect Safety Measures

When discussing the safety measures necessary for industrial electrical operations, misconceptions about motor disconnects frequently arise. One prevailing myth is that a motor disconnect is only required for large machinery. In reality, all motorized equipment, regardless of size, should be equipped with a disconnect. This is crucial not just for ensuring worker safety during maintenance but also for preventing accidental start-ups, which could lead to injuries or equipment damage.

Another common misunderstanding is that disconnects are merely shortcuts to quickly deactivate machinery. However, their primary purpose is to provide a clear visual indication that an operation is safely disconnected from its power source. This visibility is essential in a chaotic work environment where multiple tasks are being carried out simultaneously. Ignoring this can expose workers to unexpected hazards, risking their safety and potentially resulting in severe consequences.

**Tips:** Always provide clear signage around disconnects to enhance visibility and remind workers of proper safety procedures. Regular training sessions on the importance and function of motor disconnects can further reduce misconceptions and reinforce safe practices within your team. Lastly, conducting routine inspections on disconnects can ensure they are functioning correctly and ready for use in emergencies.

Importance of Motor Disconnect for Safe Electrical Operations

Related Posts

-

How to Choose the Best Motor Control Solutions for Your Needs

-

2025 How to Successfully Install Electrical Wiring Using Industry Best Practices

-

2025 Guide: How to Safely Disconnect Your Motor in 5 Easy Steps

-

How to Choose the Best Integrated Circuit Solutions for Your Projects

-

2025 Guide to Motor Control Centers: Features, Benefits, and Selection Tips

-

Essential Power Switches Tips You Need to Know for Your Home and Office

Skip to content

Skip to content