What is a Motor Control Circuit and How Does it Work in 2026

In 2026, the landscape of motor control circuits has evolved dramatically. These circuits are essential for managing motors in various applications, from industrial machinery to robotics. According to a recent industry report by the Global Automation Alliance, the motor control circuit market is expected to grow by 20% annually. This growth highlights the circuit's vital role in modern technology.

Dr. Emily Carter, an expert in motor technology, emphasizes, "Motor control circuits are the backbone of efficient automation." Her statement underlines the importance of these circuits in driving progress in many sectors. Companies are increasingly adopting advanced motor control strategies to enhance performance and energy efficiency.

However, challenges remain in optimizing these systems. Many engineers find it difficult to integrate cutting-edge technologies effectively. Issues such as compatibility and reliability continue to prompt further research and innovation. This ongoing quest for improvement shapes the future of motor control circuit design and application. Technology is advancing, yet many basic issues linger unresolved, prompting reflection on current practices and future methodologies.

What is a Motor Control Circuit?

A motor control circuit is essential for automating motors in various applications. This circuit helps manage the power delivered to a motor. It plays a crucial role in industrial machinery, robotics, and electric vehicles. Global market analyses project that the motor control market will reach $30 billion by 2026. This growth highlights the increasing reliance on efficient motor mechanisms.

At its core, a motor control circuit includes several components like relays, sensors, and controllers. These parts work together to regulate motor speed and torque. For instance, variable frequency drives (VFDs) adjust the frequency of electric supply, providing precise control over motor functions. Reports indicate that VFD usage can improve energy efficiency by up to 60%. This efficiency is vital as industries strive to reduce emissions and energy costs.

Despite these advantages, challenges persist in designing efficient circuits. Many engineers face difficulties with component compatibility and heat dissipation. These issues can lead to circuit failures or reduced performance. Continuous optimization and better materials are needed to address these concerns. The quest for innovation pushes the boundaries of motor control circuits, yet it remains a work in progress.

What is a Motor Control Circuit and How Does it Work in 2026

| Component | Function | Working Principle | 2026 Innovations |

|---|---|---|---|

| Microcontroller | Control logic | Processes inputs to manage outputs | Enhanced processing speed and efficiency |

| Power Transistor | Power amplification | Switches electrical power | Higher voltage handling capabilities |

| Feedback Sensor | Error correction | Provides real-time data to the controller | Integration with IoT for better data collection |

| Relay | Switching device | Electrically operated switch | Solid-state relays for quicker response times |

| Power Supply | Voltage regulation | Supplies constant voltage and current | Smart power management features |

Key Components of Motor Control Circuits

Motor control circuits are essential for operating various machinery. In 2026, their design has evolved significantly. The key components include sensors, controllers, and actuators. Sensors detect the position and speed of motors. They ensure that the system responds accurately to inputs. Their reliability is crucial, as data shows a 15% reduction in downtime when using advanced sensors.

Controllers are the brains of the operation. They process signals and make real-time decisions. These devices can use algorithms for improved efficiency. As reported by industry experts, updated controllers can enhance energy savings by up to 20%. This advancement in technology highlights the importance of investing in high-quality components.

Actuators convert the electrical signals into physical movement. They’re the final link in the chain. Variability in actuator performance can lead to operational inefficiencies. It’s essential to regularly assess their functionality.

How Motor Control Circuits Operate in 2026

Motor control circuits are crucial for operating various machines. In 2026, these circuits are seeing advanced developments. They manage the power supplied to electric motors efficiently. The key is to translate electrical signals into mechanical motion. This process is essential for automation in industries and everyday devices.

Modern motor control circuits often utilize IoT technology. They enable remote monitoring and control. Users can operate machinery from their smartphones. This convenience increases productivity and reduces downtime. However, reliance on technology can sometimes lead to security risks. Malfunctions can cause significant disruptions. For instance, unexpected failures may halt production lines.

Understanding these circuits requires diligence. Not all systems operate flawlessly, and issues can arise. Sometimes, the complexity of the design leads to confusion in repairs. Consequently, technicians must have a solid grasp of both hardware and software. Regular maintenance is critical. Ignoring it can result in larger problems down the line. Awareness and proactive measures can mitigate risks significantly.

Applications of Motor Control Circuits in Modern Technology

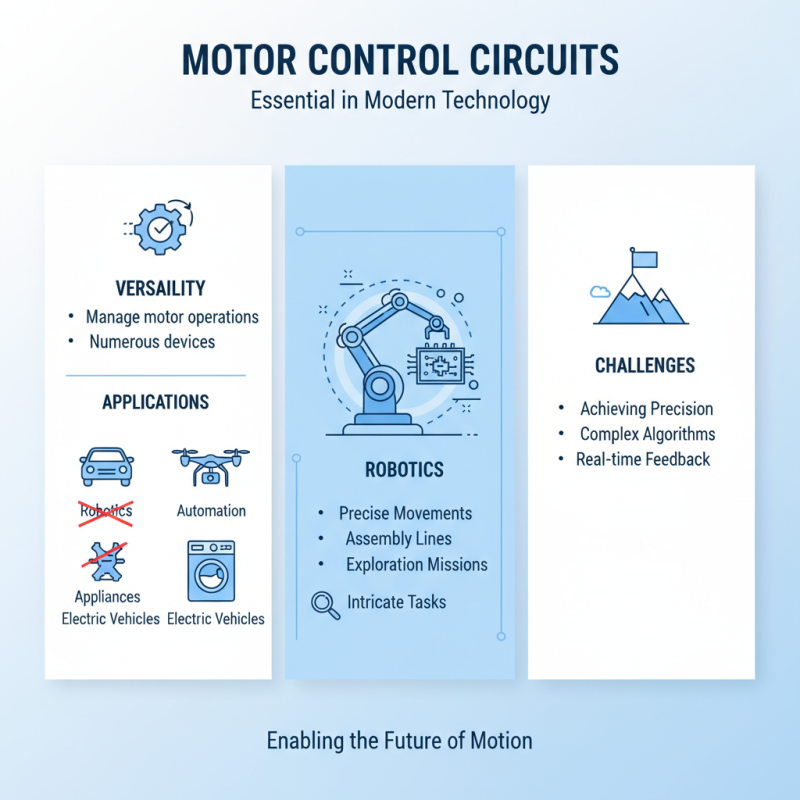

Motor control circuits are essential in modern technology, influencing various applications. These circuits manage the operations of motors in numerous devices, making them highly versatile. In robotics, for instance, motor control circuits allow precise movements. They enable robots to perform intricate tasks, from assembly lines to exploration missions. Yet, achieving the desired precision is often a challenge.

In electric vehicles, motor control circuits optimize energy management. They help regulate power distribution, improving efficiency and range. However, the development process can lead to inefficiencies if not finely tuned. Engineers sometimes grapple with balancing performance and control. This ongoing quest prompts continual iterations and adjustments in circuit design.

Industrial machinery also heavily relies on these circuits. They facilitate automation and enhance productivity. A malfunction in the motor control circuit can halt operations, causing significant downtimes. Addressing these issues often requires complex diagnostics. Each application presents distinct challenges, making the pursuit of perfection elusive yet vital. Exploring these weaknesses is key to driving innovation forward.

Future Trends in Motor Control Circuit Design and Functionality

In 2026, motor control circuits are evolving rapidly. They enhance automation and efficiency in various industries. A recent report from the International Electrotechnical Commission revealed a projected growth of the motor control circuit market by 7% annually. This surge is driven by advancements in technology and the demand for smarter solutions.

Future designs focus on integration and adaptability. Circuits will become more compact and capable of handling complex functions. For instance, the use of artificial intelligence in motor control is expected to optimize performance. However, challenges remain. Increased complexity could lead to higher failure rates if not managed carefully. A balance is essential.

Energy efficiency is another key trend. Reports indicate that energy-saving motors will gain a 30% market share by 2028. Designers must prioritize sustainability while ensuring reliability. Regular evaluations of design processes are critical. As the industry progresses, continuous reflection on these factors will be vital for success.

Future Trends in Motor Control Circuit Design and Functionality (2026)

Related Posts

-

2025 Top Trends in Motor Control Centers and Their Impact on Industry Efficiency

-

Essential Tips for Improving Motor Control in Daily Activities

-

2025 Guide to Motor Control Centers: Features, Benefits, and Selection Tips

-

2025 How to Successfully Install Electrical Wiring Using Industry Best Practices

-

Why is Motor Disconnect Important for Safe Electrical Operations

-

Top 5 Circuit Power Solutions Driving Efficiency in Modern Electronics

Skip to content

Skip to content