Why Are Soft Starters Essential for Motor Control and Energy Efficiency?

Soft starters play a crucial role in modern motor control and energy efficiency. These devices help manage the starting current of motors, reducing electrical strain. According to a report by the International Energy Agency, inefficient motor start-up can consume up to 60% more energy than necessary. This is a significant concern for industries aiming for sustainability.

The continuous demand for reliable motor operation has made soft starters essential. They ensure a smoother ramp-up of motor speed, minimizing mechanical stress. This reduction in stress can extend the lifespan of motors, leading to lower maintenance costs. However, many industries still overlook these benefits, impacting their efficiency.

Despite the clear advantages, some remain hesitant. The initial cost of soft starters can deter investments. Yet, considering long-term savings, these devices often pay for themselves. Reflecting on current practices, adopting soft starters can lead to more significant energy savings and enhanced operational stability.

Overview of Soft Starters and Their Functionality

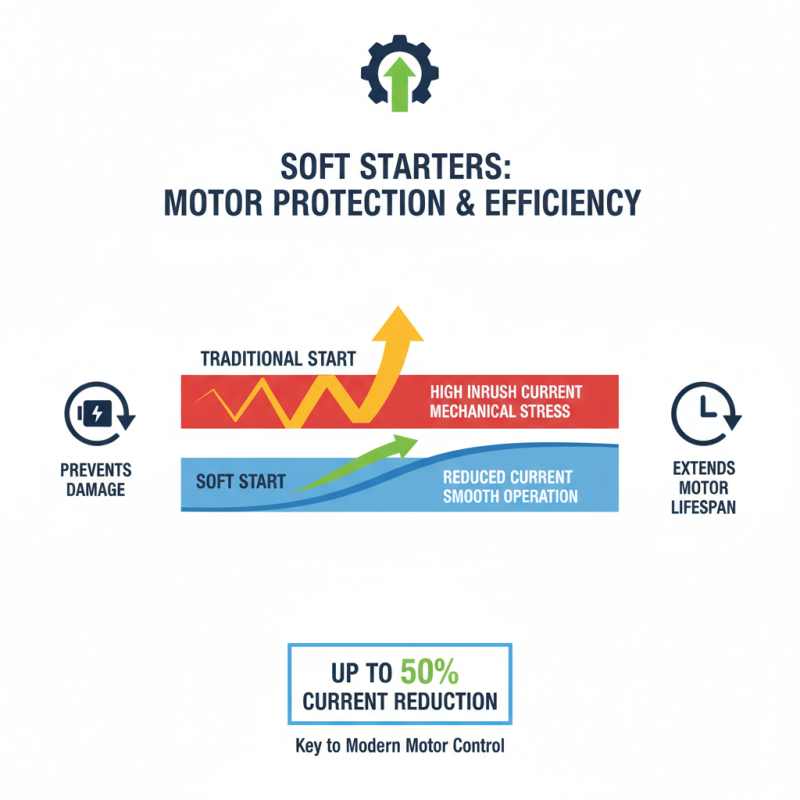

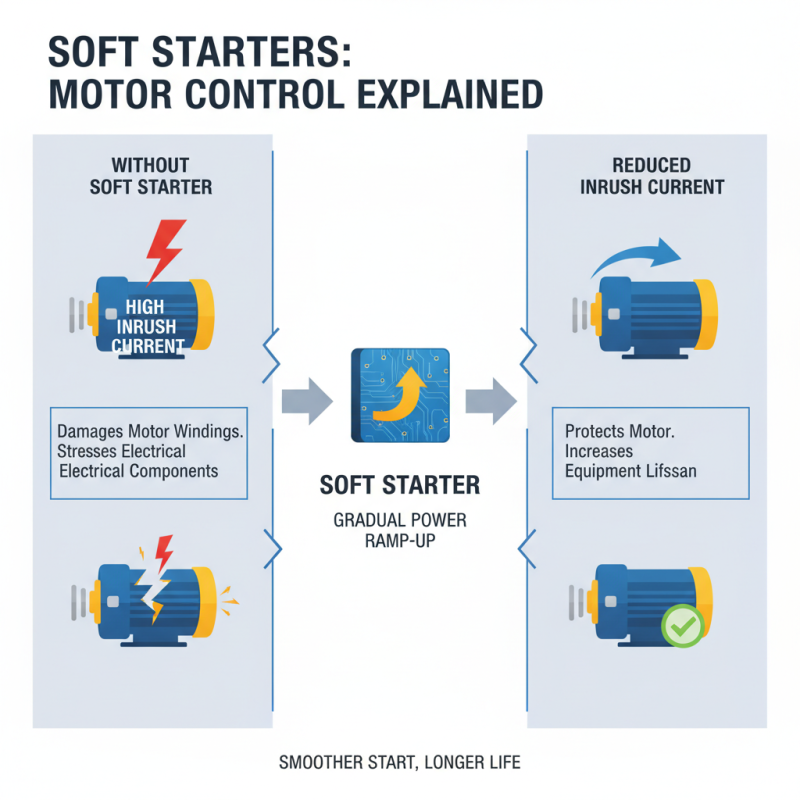

Soft starters play a crucial role in modern motor control. They regulate the starting and stopping of electric motors, reducing mechanical stress. When machines start abruptly, they can experience high inrush currents, often leading to damage. Reports show that using soft starters can cut startup current by up to 50%. This protection extends motor lifespan significantly.

In energy efficiency, soft starters contribute to reduced energy consumption. A study noted that controlling acceleration can save approximately 30% energy in industrial applications. This efficient control means reduced operational costs. Furthermore, soft starters can mitigate voltage dips caused by large machines. This stability ensures other equipment remains operational, minimizing downtime.

However, not all users recognize the value of soft starters. Some may hesitate due to initial investment costs. That’s a misconception. The potential long-term savings often outweigh the upfront costs. Ignoring these advantages can lead to unexpected maintenance and higher energy bills. The choice is clear: effective motor management is essential for sustainability and efficiency.

Benefits of Using Soft Starters in Motor Control

Soft starters play a crucial role in motor control. They help reduce the inrush current that occurs when motors start. This is important because high inrush currents can damage motor windings. With a soft starter, the motor ramps up slowly. This gradual increase minimizes stress on the electrical components.

Energy efficiency is another key benefit. Traditional motor starting methods waste a lot of energy. In contrast, soft starters provide smoother acceleration. This results in less energy consumption. It can lead to significant cost savings for businesses over time. Additionally, they can improve the lifespan of the motor, leading to fewer replacements.

However, it’s important to note that not every application needs a soft starter. Some motors work well without them. It's essential to assess the specific requirements before deciding on installation. Relying solely on soft starters may lead to missed opportunities for optimization in certain scenarios. Understanding your system is key.

Impact of Soft Starters on Energy Efficiency

Soft starters are crucial for enhancing motor control and improving energy efficiency. By gradually ramping up the power, they minimize the initial surge that can cause stress to motors. This soft starting mechanism leads to less wear and tear and prolongs motor life. Ultimately, this contributes to reduced maintenance costs over time.

When evaluating energy efficiency, consider how soft starters can help stabilize energy consumption. They protect against voltage dips and spikes during start-up phases. This control prevents unnecessary energy waste and can lead to better overall plant efficiency. The combination of starting gently and maintaining steady operation optimizes performance.

Tips: Regularly check soft starter settings to ensure proper function. Misconfigurations can lead to inefficient performance. Also, monitor motor performance regularly. Recognize any unusual vibrations or excessive heat as signs of inefficiency. Identifying these issues early can save significant energy and costs. The goal is to create a balance between performance and energy savings. Reflecting on these factors helps in refining operational strategies.

Applications of Soft Starters in Various Industries

Soft starters play a crucial role in various industries by controlling motor starts and stops. These devices gradually ramp up voltage, reducing inrush current. This approach minimizes mechanical stress on equipment, leading to longer service life. For example, in the manufacturing sector, soft starters can protect conveyor belts from damage, ensuring smoother operation.

In HVAC systems, soft starters help manage the large motors that drive fans and compressors. By preventing sudden starts, they enhance energy efficiency. The smooth acceleration also leads to quieter operation. However, some facilities still overlook this technology. Many are hesitant to invest time and effort into a transition.

The benefits of soft starters extend to renewable energy applications as well. Wind turbines and solar tracking systems rely on them for optimal efficiency. Still, installation often faces delays due to initial costs. Industries sometimes underestimate the long-term energy savings and maintenance reductions. These factors deserve further consideration.

Key Considerations for Selecting Soft Starters

When selecting soft starters, several key considerations come into play. First, the motor's horsepower is crucial. Soft starters need to match the specific power requirements of the motor for optimal performance. For instance, a 25% energy demand can occur during motor start, which may harm both efficiency and longevity. It's vital to check the starter's capacity. Often, systems with variable loads require tailored solutions.

Another essential aspect is the design of your application. For instances with frequent starts and stops, choose a soft starter designed for such conditions. A study by the National Electrical Manufacturers Association (NEMA) indicates that proper motor control can reduce energy consumption by up to 30%. Undoubtedly, this can lead to significant savings over time.

Tips: Look for soft starters that have adjustable settings. This allows you to fine-tune the motor's performance to suit your needs. Ensure the soft starter has built-in protection features. These safeguard against overloads and short circuits, enhancing system reliability. Finally, consult with a professional to evaluate your specific requirements. Their expertise can help identify potential pitfalls in your selection process.

Related Posts

-

How to Choose the Right Soft Starters for Your Industrial Applications

-

2025 Top Trends in Motor Control Centers and Their Impact on Industry Efficiency

-

Top 10 Tips for Choosing the Best Power Controller for Your Needs

-

Top 10 Electric Motor Controller Features You Need to Know

-

What is a Motor Control Circuit and How Does it Work in 2026

-

Essential Tips for Improving Motor Control in Daily Activities

Skip to content

Skip to content